Ever since Glock made its debut into the LE world back in the late 1980s, there has been a quest to "perfect" its trigger. In truth, compared to many of the triggers on police pistols at the time, the Glock trigger was a huge advancement. But boy's being boys, the tinkering began. The quest seemed to take the path of making the triggers as light, and with as minimal take-up, as possible. Then with a good amount of judicious polishing, the officer ended up with a completely unsafe pistol, albeit with a wondrous trigger. And of course, since every Glock owner fancies himself a qualified gunsmith the moment they sign that 4473, the quest caught like chicken pox at a public school.

TRIGGER MECHANICS - THE FEEL

Now look...you can have a great trigger that is quite safe on a Glock, but you must accept that it will never have a trigger like a tuned 1911 or a single action revolver. But lets define the components parts of the trigger so you understand what is possible with a great Glock trigger.

TAKE UP: First we have the segment of the trigger called "take up". Sometimes this is called "Pre-Travel". It is the light initial movement of the trigger when the finger begins pressing it rearwards. It is defined by us as the first stage of what is a two-stage process. This stage can be minimized but not eliminated. Even a tuned 1911 has a degree of this early free movement. Elimination of any pre-travel could make the trigger unsafe. A pistol with zero pre-travel in its trigger should not be carried for self-defense.

But pre-travel will not affect accuracy, nor will it diminish your marksmanship as long as that pre-travel feels smooth and is free of perceptible spring tension.

BREAK: The completion of the pre-travel leads to a stopping point. At that stopping point, also known as "the wall", any additional pressure will begin to break the trigger and fire the shot. The breaking through the wall should be sudden and crisp. Jeff Cooper described the prefect trigger feel like a glass rod breaking. The issue with many production pistols is that the trigger break is gritty, drawn out and spongy. You can certainly gunfight with such a trigger, but it is not optimal. On a Glock, that "glass rod" is best attained via an aluminum trigger.

With work, polymer on polymer can work, but its easier with aluminum. As well, the quality of springs used will affect how the trigger feels. Lighter may not always yield a better feel.

OVER-TRAVEL: Sometimes gun writers get very worked up about over-travel, but I have found it to be a non-issue. Over travel is any additional rearward movement of the trigger after breaking the shot. Why is this not a big deal? Because the weapon is already firing and you are at the arc of the recoil. Sometimes guys will want to add special screws and pins and so on to eliminate over travel. Again, for our purposes you needn't waste your time with this concern.

RESET: Of greater importance is the trigger reset. As the trigger is allowed to move forward again, that movement should be short, crisp, and predictable. One of the problems we have always had with the S&W for example has been an often nebulous trigger reset. This causes students to move that trigger further forward than necessary. With a proper Glock trigger you will hear that reset and feel it very distinctly. Again this is a product of a smooth trigger surface and the use of proper springs.

Lets discuss trigger weight. A good combat trigger need not be a light trigger. In fact a light trigger is often undesirable. On my personal triggers I use factory Glock 3.5# connectors. Those coupled with 4.5 pound to 5.0 pound striker springs will yield approximately a 4 pound trigger weight. Combine that workable weight with a smooth as glass trigger and a crisp break, and you have the makings of the ultimate combat trigger on a Glock pistol.

TRIGGER MECHANICS - THE INTERNALS

No production pistols will have perfect and completely uniform tolerances. No matter what the engineers tell us in their ads, there will be a degree of variance in frames, firing pins and other components. We have seen Glock 21 magazines fit perfectly into one frame, yet fit excessively tight in another. We have seen the same thing with certain other components. This means that even though most parts will fit most guns, the end user will need to verify that fit before moving on. When those engineers assemble a pistol at the factory, they make sure all the components work properly and within the acceptable tolerances. When the end user changes parts, he must take this into consideration.

As far as triggers and trigger components go, it is imperative for the end user to check everything, and to do so periodically. You cannot just drop the parts in, load the blaster and go off into the world. A thorough technical check followed by a range visit to make sure function is mandatory. And as much as the DIY community hates to hear it, some of this might be best done by a gunsmith.

Make no mistake, just like the brakes on your car, pistol components wear out and must be checked as well as replaced regularly. Thinking that a pistol and its components will last forever with no wear and no need for maintenance and parts replacements is foolishness.

If you cannot or don't want to do that, then leave your trigger alone.

Here is the Trigger Installation And Safety Checks discussion from our store that every Glock owner must read

For most users, all these trigger components are a drop-in fit. Regardless, our policy is that this trigger must be installed by a Glock Armorer or professional Glock Gunsmith. If you are not a skilled Glock Armorer, take it to someone who is. If you damage any of the parts attempting to improperly install it, we will not accept it back.

Always insure the pistol is unloaded and that there is no way to mistakenly load it while working or installing these components. This trigger is not recommended for novice shooters, untrained shooters, or anyone not familiar with standard gun safety practices.

Once the trigger has been installed, and you have made certain the pistol is unloaded, you must dry press and cycle the weapon several times to get an understanding of how this trigger system's ergonomics work and feel different than the factory Glock trigger.

Do not load a pistol equipped with this trigger without becoming familiar with these differences. As always, keep your finger off the trigger.

Changing springs and components may affect the dynamics and reliability of the trigger. We cannot guarantee, nor will we warranty our triggers to function reliably with any other company's components. As always, adhere to standard firearm safety practices and do not load a pistol equipped with this trigger without becoming familiar with these differences. Disassembly of the trigger will instantly void any warranty.

Glock® Trigger Safety Checks

Trigger Safety checks (must be done periodically to check for wear): These safety checks are applicable to any Glock® trigger, stock or aftermarket, and should be performed regularly to ensure all safeties are functional. Ensure weapon is unloaded and no ammo is present for safety checks. Many aftermarket triggers can fail to be firing pin safe but do offer some level of compromised drop safety.

1) Check trigger safety to ensure it is engaged when weapon has been racked. Without engaging the trigger safety bar firmly press the trigger to attempt firing. Ensure that the trigger safety does not slip off resulting in firing. If slipping occurs your weapon is no longer drop safe or firing pin safe, ensure it is repaired before use. Additionally, the safety plunger will see wear. If it, or any other part in the trigger linkage, appears worn it is imperative the user change them immediately.

2). With the slide removed and trigger installed pull trigger forward so that it is resting on the trigger safety. Press the trigger bar on the cruciform at that trigger housing. Ensure that the trigger bar will not drop in a manner that could result in striker release. If the trigger bar drops into the housing, your weapon is not drop safe, ensure it is repaired before use.

3). With the slide assembled but back plate removed and striker not engaged with the trigger bar, pull the trigger forward so that it is resting on the trigger safety and ensure that the firing pin is blocked and cannot move forward. This is best done using a Glock armorer’s tool and pressing the rear of the firing pin firmly with the armorer’s tool to ensure the firing pin cannot slip past. If the firing pin can slip past the safety plunger, your firing pin safety is not functional. Ensure your trigger is repaired before use. Finally pull the trigger and ensure the firing pin moves freely past the safety plunger. If firing pin is felt to be impacting or slipping by the safety plunger, this can sometimes result in light primer strikes and should be repaired or over travel adjusted before duty or self-defense use. The easiest way to check for safety plunger interference is to perform the “rattle test”. If it, or any other part in the trigger linkage, appears worn it is imperative the user change them immediately.

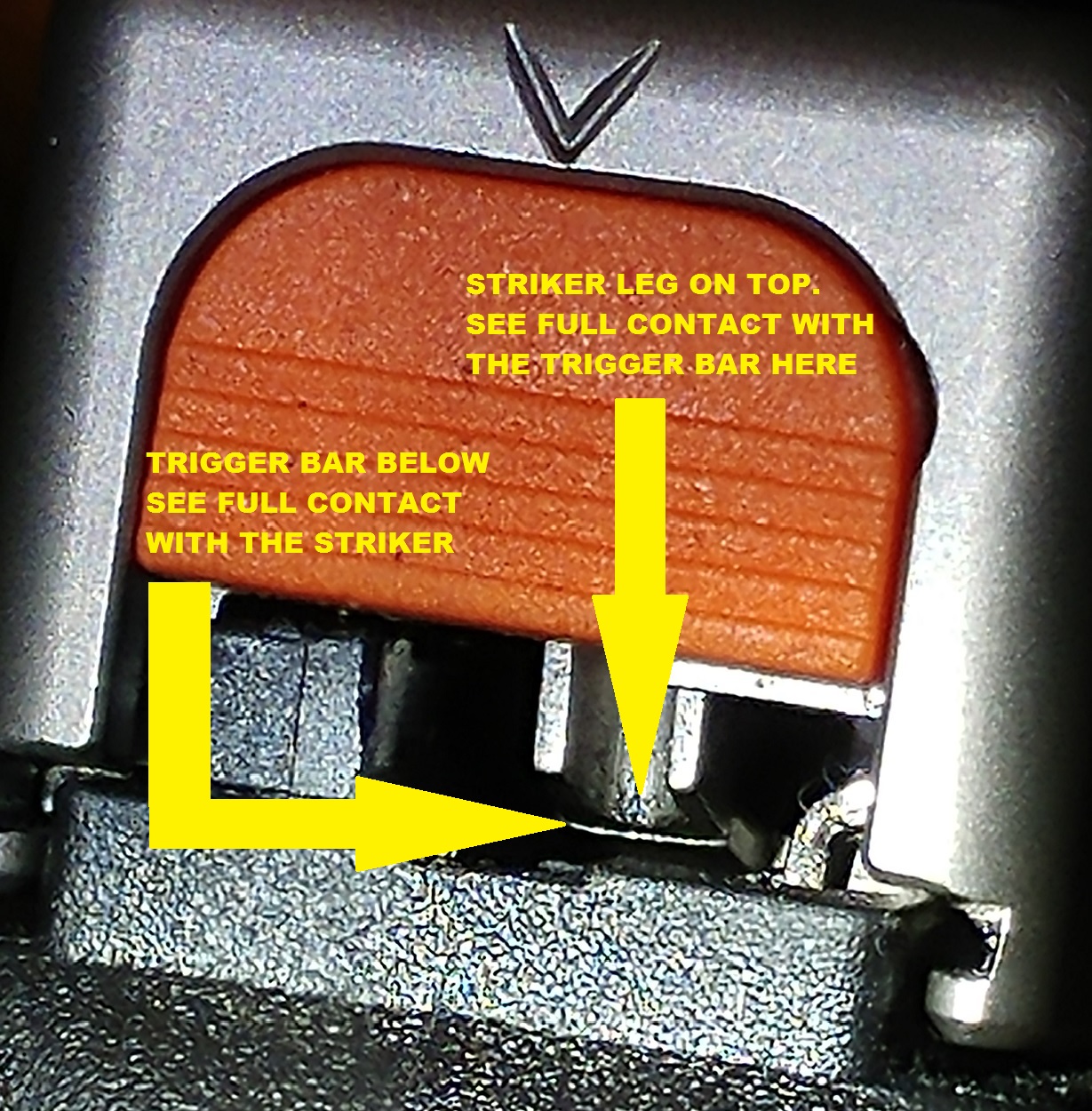

4). Install a Glock armorer's back plate or look underneath the standard back plate and check for 2/3 to full firing pin to trigger bar engagement (sear engagement) when firearm is racked. As an additional reliability check, check sear engagement on reset while holding trigger depressed. Sear engagement on reset should be closer to 3/4 to full engagement to ensure long term reliability.